Despite all industrial progress since the foundation of the Boker Manufactory in 1869, some historic production methods are still used for making a Boker straight razor. We definitely preserved the passion, experience and perfection in choosing our materials and executing each of the production steps we would like to explain to you here. At the forge, the basic material is a round rod cut to length to create the so-called cropped piece. The splitter is heated until red hot, and drop forged with a 1,500 lb rammer. Next, the slugs have to cool to 392° F for two days in an annealing furnace. The slugs are once again straightened in a 200-ton press, before going to the hardening shop. By thermic treatment the perfect combination of edge-holding property and flexibility of the steel is created. In the grinding shop, the extra hollow grind with belly is created. The slugs are ground in 18 individual steps, from rough grinding, to milling, to glazing. We exclusively grind our straight razor blades extra hollow with belly. The belly lies in front of the strong hollow section and just behind the edge, which has a small hollow grind itself. The belly is the only way in which the blades can be ground out so thin and still retain sufficient stiffness, despite their flexibility. There are only a handful of the best and most specialized grinders in the world that have mastered this ultimate skill in straight razor production. The scales department manually assembles nickel silver pins, washers, and spacers to the blades. Wood and stag require special dexterity, as these natural materials can tear when too much pressure is applied. Finally, the blade is honed by hand on several bench whetstones with increasingly finer grits. After the final stropping, the sharpness of the straight razor is tested on a freely suspended human hair.

Widths and Heads

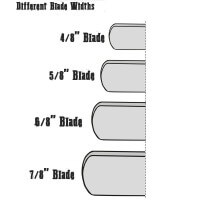

The shapes of straight razors are mainly determined by national and local traditions and personal preferences. However, the different shapes have different benefits. An 8/8“ blade is one inch wide, a 4/8“ blade half an inch wide. The 5/8“ blade is the most common width. Below 4/8“, the blades are used mainly by hairdressers to shave the neck, or for contouring. A wide blade glides over the skin more steadily, due to its weight, and can take on more soap and beard hairs before having to be wiped. Narrow blades are better for working on inside curves and contouring. There are various point/head shapes as well – the rounded point, the straight point, the French point, and the Spanish point. The round point is the easiest to handle. It is thus very suitable for beginners. The defined edges of the other heads provide benefits for the precise creation of contours.

Holy f***

It's been a month and I paid for my order fill it and send it for f*** sake.

knife manufacture

I just read your latest blog post, “Construction and Manufacturing of a Razor” and it was truly insightful. I appreciated how you presented the topic with well-researched information. The section about Razor was particularly interesting and inspired me to learn more. Your engaging writing style and logical flow made it easy to follow. Thanks for the valuable resources. I’ll keep following your blog! https://www.baramdat.com/blog